This is part of our series of blog posts designed to help customers understand their vehicle better. Please keep in mind these are general descriptions of how these modules function. There are differences in many years and models, but generally the principles remain the same.

What Is FlexRay?

Modern vehicles are packed with advanced technology. From adaptive suspension systems to sophisticated driver-assist features, modern vehicles rely on high-speed communication between dozens of electronic control modules. One of the most important technologies that makes this possible is FlexRay.

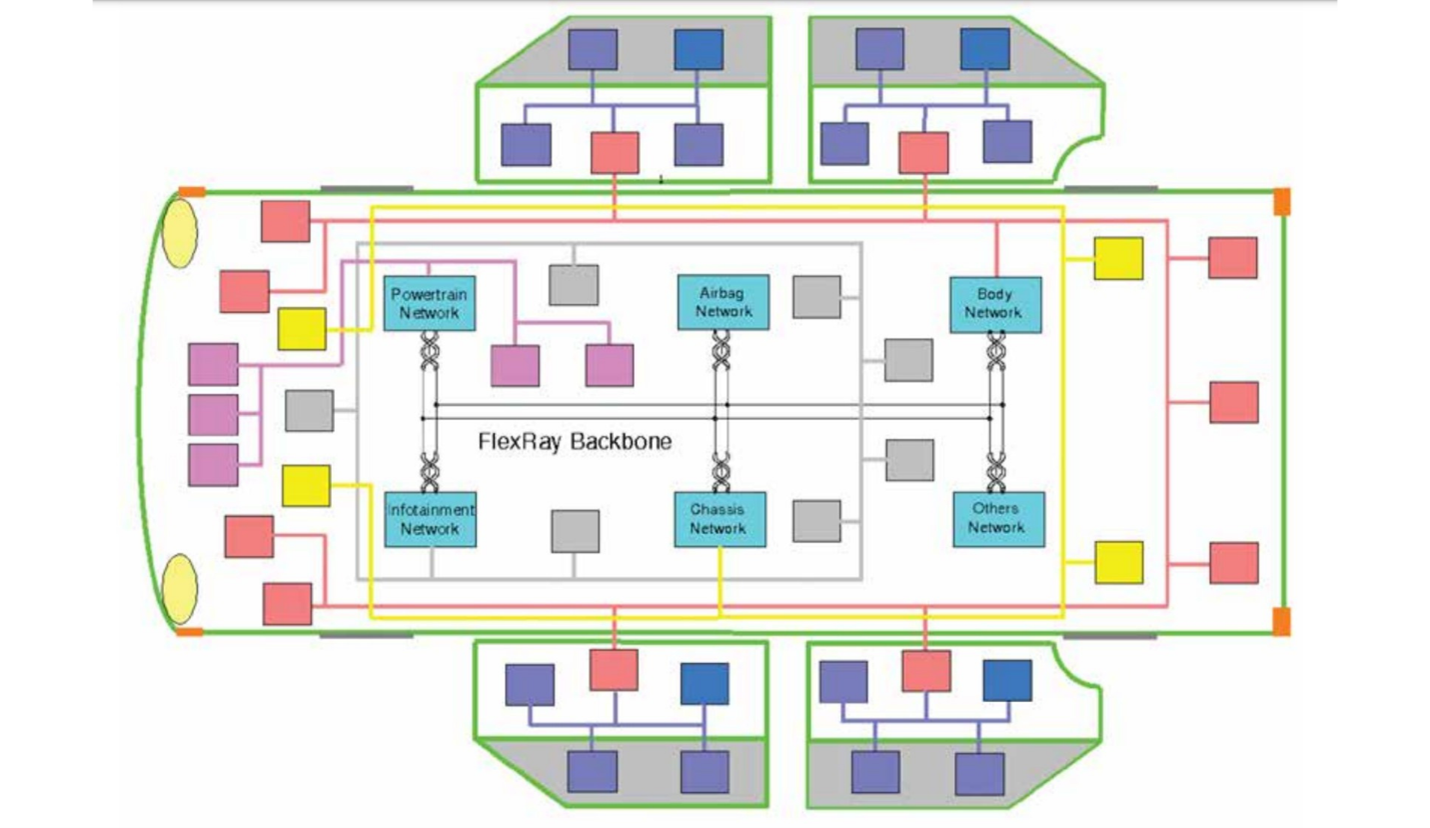

FlexRay is a high-speed, fault-tolerant communication protocol used in many modern vehicles. Think of it as a “superhighway” that allows different modules in your car, like the suspension control, braking, and steering systems, to talk to each other instantly and reliably.

While older systems like CAN (Controller Area Network) work well for basic communication, they have limitations in speed and data precision. FlexRay was designed to handle more complex tasks, such as real-time control of safety-critical systems.

In very simple terms: FlexRay enables the precise coordination that today’s advanced automotive systems demand.

How Does FlexRay Work?

At its core, FlexRay operates by transmitting digital messages along specialized wiring at very high speeds (up to 10 Mbps). Here’s what makes it unique:

Time-Triggered Communication: Unlike CAN, where messages are sent whenever there’s room on the bus, FlexRay uses a synchronized “schedule.” Each module knows exactly when it can send and receive data, which eliminates delays and ensures critical systems respond instantly.

Dual-Channel Redundancy: FlexRay can operate on two separate channels. This not only doubles bandwidth if needed but also provides backup communication if one channel fails, which is important for safety-critical systems.

Fault Tolerance: Because of its design, FlexRay can continue operating even if part of the network develops a fault, making it highly reliable.

This structure is what allows systems like electronic suspension, steer-by-wire, and advanced stability controls to function seamlessly.

Why FlexRay Modules Are Complex to Repair

Modules that operate on FlexRay aren’t like ordinary automotive electronics. They require:

- Specialized diagnostic equipment to communicate with the FlexRay network.

- Deep technical understanding of scheduling, timing, and synchronization between modules.

- Advanced repair processes to ensure the module works correctly within a highly coordinated system.

For most companies, this level of complexity is a barrier. Missteps can cause critical safety systems to malfunction.

How XeMODeX Makes the Difference

At XeMODeX, we’ve invested in the knowledge, training, and equipment needed to understand and work with FlexRay technology. Our engineers have developed custom tools and processes that allow us to diagnose, repair, and test these advanced modules to factory-level standards or better.

Because of this investment, we can repair modules that most other companies won’t even attempt. When a FlexRay-equipped system fails, XeMODeX is uniquely positioned to provide a reliable, lasting solution.

The Bottom Line

FlexRay is the backbone of many advanced vehicle features, ensuring safety and precision where it matters most. But its complexity means repairing FlexRay modules requires more than basic electronics knowledge. It demands specialized expertise.

That’s where XeMODeX stands out. By mastering the fundamentals of FlexRay communication and investing in cutting-edge diagnostic technology, we make repairs possible that others can’t.

Visit www.xemodex.com to check out our products and services.