This is part of our blog series dedicated to providing information about how the electronics in your vehicle work. The goal is to help inform our customers so they can make the best possible decision for their vehicle.

When diagnosing issues in electronic modules, one of the most common problems we encounter at XeMODeX is cold solder joints. These defective connections can cause intermittent failures, loss of functionality, and, ultimately, complete system failures. Understanding what cold solder joints are and how to prevent them is essential in ensuring reliable, long-lasting repairs.

What is a Cold Solder Joint?

A cold solder joint occurs when a solder connection fails to properly bond with the component lead or PCB pad. This usually happens due to:

- Insufficient Heat: The solder does not fully melt and flow around the joint.

- Contaminants: Dirt, oxidation, or flux residue prevents proper adhesion.

- Movement During Cooling: If a component moves before the solder solidifies, it results in a weak bond.

- Improper Solder Application: Too little or too much solder can create weak or unreliable connections.

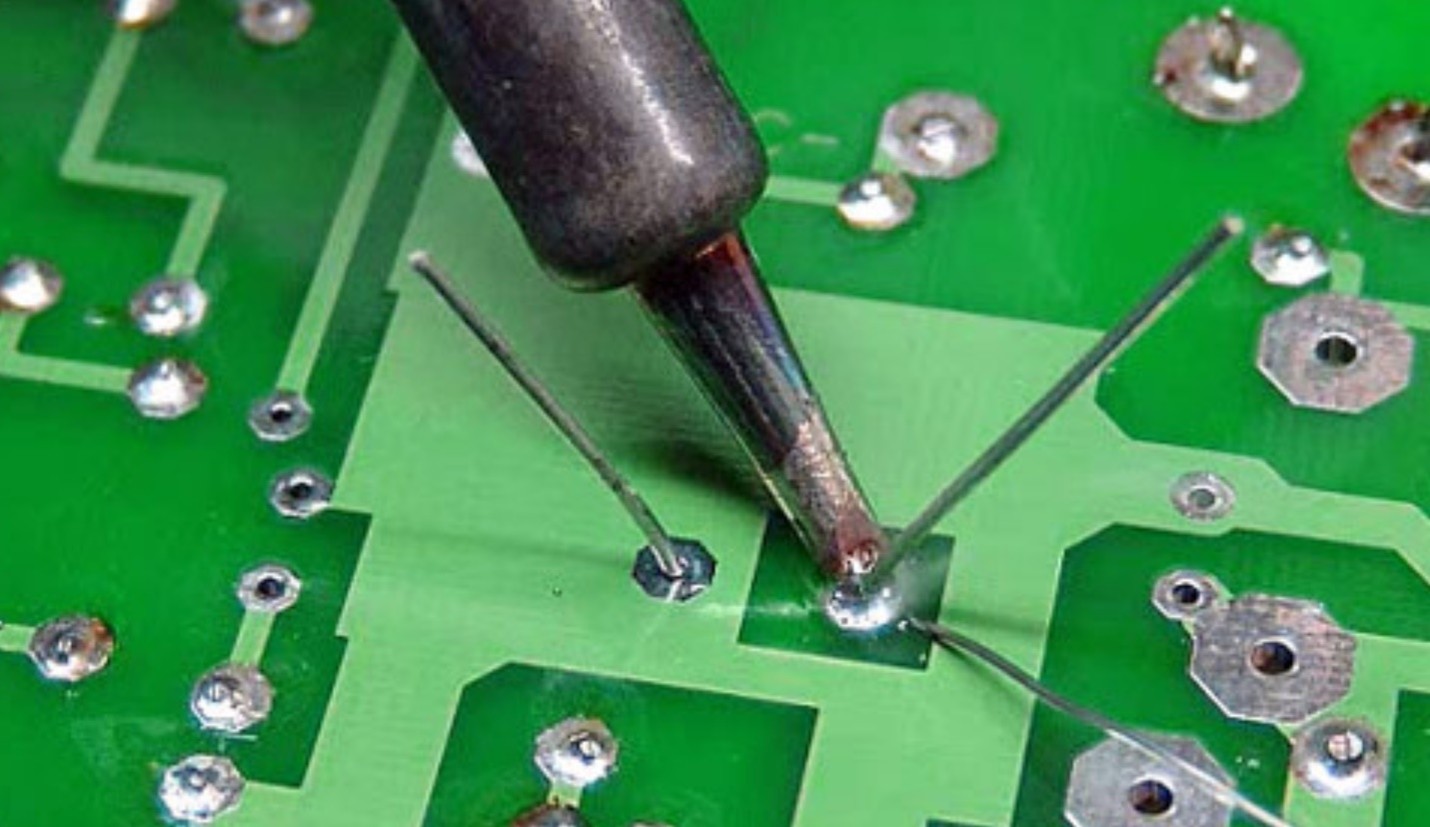

Visually, cold solder joints may appear dull, grainy, or cracked. Unlike a proper solder joint, which is shiny and smooth, these defective joints often lead to poor electrical conductivity and eventual failure.

The Impact of Cold Solder Joints on Electronic Modules

Cold solder joints can create a variety of issues, including:

- Intermittent Electrical Contact: This can cause erratic operation, leading to system malfunctions.

- Increased Resistance: Poor connections generate excess heat, potentially damaging surrounding components.

- Complete Circuit Failure: Over time, a weak solder joint can break entirely, resulting in a non-functional module.

While cold solder joints may seem like a simple and straightforward issue, improper repairs can actually make the problem worse in the long run. If a repair is not done correctly, the joint may fail again, potentially causing further damage to the PCB and surrounding components. This is why it is essential to have electronic modules repaired by a reputable company like XeMODeX, where expertise and high-quality workmanship ensure a lasting fix.

These issues are particularly problematic in automotive electronics, where vibration, temperature changes, and continuous operation put stress on soldered connections.

XeMODeX’s Commitment to High-Quality Repairs

At XeMODeX, we understand the critical role that reliable soldering plays in electronic repairs. That’s why we take the following steps to ensure high-quality, durable repairs:

- Advanced Soldering Techniques: Our technicians use precise temperature control and proper soldering methods to create strong, lasting bonds.

- Thorough Inspection and Testing: Each repaired module undergoes meticulous visual and functional testing to ensure every joint is solid and reliable.

- Use of High-Quality Materials: We use industry-leading solder and flux materials to enhance durability and conductivity.

- Reinforcement of High-Stress Points: To prevent failures, we reinforce known weak points to improve the overall reliability of the module.

By prioritizing superior craftsmanship and attention to detail, we prevent recurring issues and extend the lifespan of the repaired electronic modules. When you choose XeMODeX, you can trust that your module is receiving the highest standard of care, ensuring reliable performance for years to come.

Visit www.xemodex.com to check out our products and services.